Infrastructure

FABRICATION PROCESS

FABRICATION PROCESS

CUTTING MACHINE ALTENDROF-WA8

EDGEBAND BIESSE JADE -335

Jade 300 is the range of automatic single-sided edgebanding machines designed for artisan craftsmen who want to improve and automate production, or for industry sectors manufacturing made-to-measure products

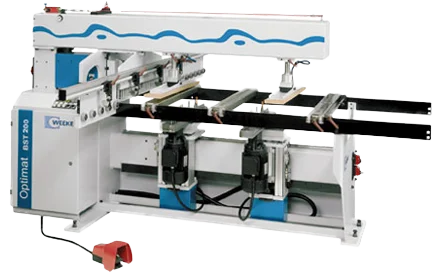

MULTIHEAD BORING HOMAG BST 200

This model has three drill heads (one horizontal and two-vertical) to 21 in each spindle with axial distance of 32 mm. Rotary vertical drilling heads allow locking in the 0 °, 45 ° and 90 °. Positioning of the workpiece is made with aluminum line length 2200 mm, with the help of 4 (two left and two right) sliding stops.

Active Edge 60

The Active Edge 60 is the new compact, semi-automatic edge banding machine for straight and shaped panels. Plug & Play: It is very simple to install, operate and maintain. It is capable of applying edges in rolls (melamine, ABS, PVC, veener) and in strips (formica, solid wood)

Semi-Automatic 3 Phase Plywood Cold Press

This model has three drill heads (one horizontal and two-vertical) to 21 in each spindle with axial distance of 32 mm. Rotary vertical drilling heads allow locking in the 0 °, 45 ° and 90 °. Positioning of the workpiece is made with aluminum line length 2200 mm, with the help of 4 (two left and two right) sliding stops.

INSTALLATION

Request the client to take a leave from their home for the day. It would help us keep the work area to ourselves and not have ancillary things to have at the back of our minds.

2. Conduct a purchase audit at least a week prior to the installation day to ensure the procurement process for the items to be moved is complete.

3. If the project is expansive, you can hire extra helpers for the day to keep things smooth and moving.

4. Create a list of items to be handed over to the movers and doubly check if everything is included.

5. Make sure you include everything in the toolkit and the installation kit. Double-check it. Or maybe triple-checking would suffice.

6. Print multiple floor plans and at least have a copy for each room. It would bring about coherence in the Interior process and would also enable the movers to place the items accordingly.

7. Pack in faith, chocolate, good humor, and snack for the installation day.

8. Shop for final items, such as decor, flowers, drapery hooks, pillow inserts, cleaning supplies, and more in bulk (more than needed).

9. Wear comfortable shoes and clothes to help you move swiftly. It is an unsaid hack for having a field day at work.